Regcabguy

Oil eater.

DOR's going to be producing one for us 3rd gen guys soon. I wonder if it's such an issue with our much stiffer hydroformed frames?Nice build! Not many of us 2nd gen Rams out there being built. Wanted to pass along some info on that steering brace though. I recently removed that style and installed a new one made by Dodge Offroad that only mounts on the driver side frame rail. The design you have works great on the road, but our frames have so much frame flex in them that one rail will actually pull the output shaft while articulating and cause a leak that eventually becomes a bad seal.

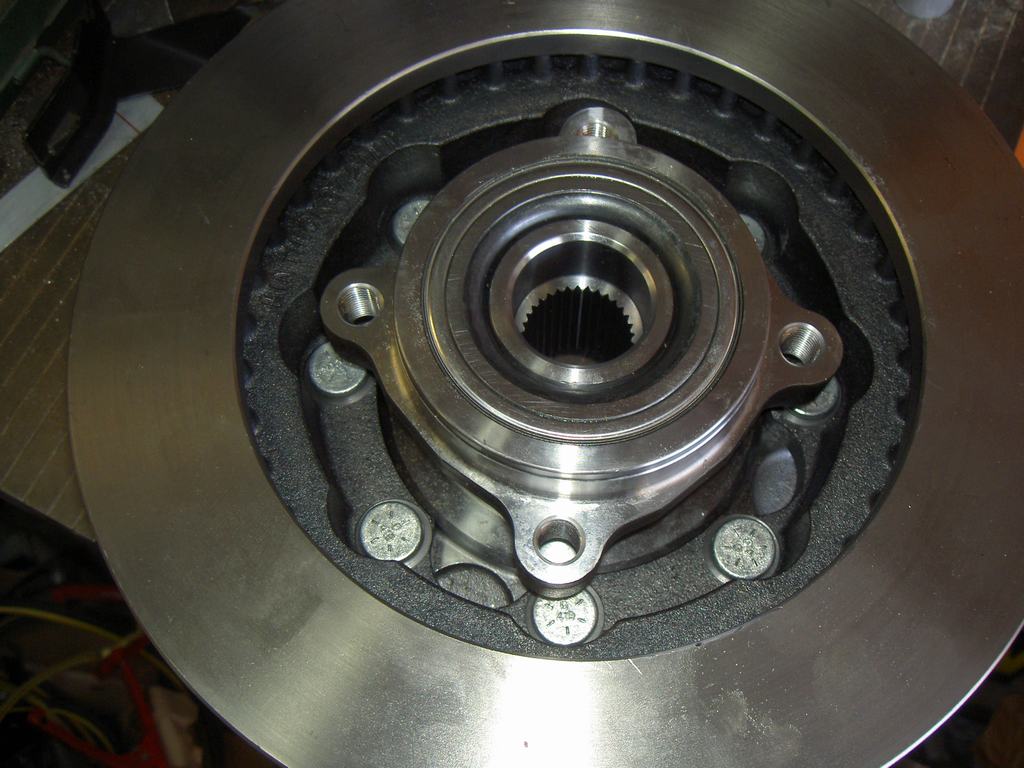

Here's my truck and the new support:

Here's the website.

http://www.dodgeoffroad.com/store_DORbrace2g.php

I'm hoping to start a thread on here soon. Even though it's more of an offroad rig than an expedition rig right now, I have plans to build a bed-top tent and convert a HMMWV trailer to a tow-behind everything else.

Last edited: