Awesome! I love when people make custom stuff like that!

Thanks!

I really wish I had some of your electrical knowledge and access to the machinery that you do!

This is an excellent thread that we can all learn a lot from!

If you feel the need and/or have the time, I wouldn't mind you getting even more technical with info and pictures. Not only do I have an endless capacity for useless knowledge(well, useless when applied to my own build), but in 10yrs, someone may value this thread greatly doing a similar swap.

Keep up the great work!

Thanks Baja - I'm trying to document this build as best I can for future swappers

Did some work on the transfer case this weekend. I picked up a first gen S10 231 to get my input shaft and 6 pinion planetary. Just for reference I was reading a couple S10 forums and a few guys said that all of the original body style S10 231 cases (82-93) have 6 pinion planetaries and wide chains. The downside is its the old style gear cut so it may be a little louder than the newer style. Everything I have read says the gear cut changeover year is 94 so if you are using the older style like me grab a 93 or older case or 95 or newer if you are using the newer cut.

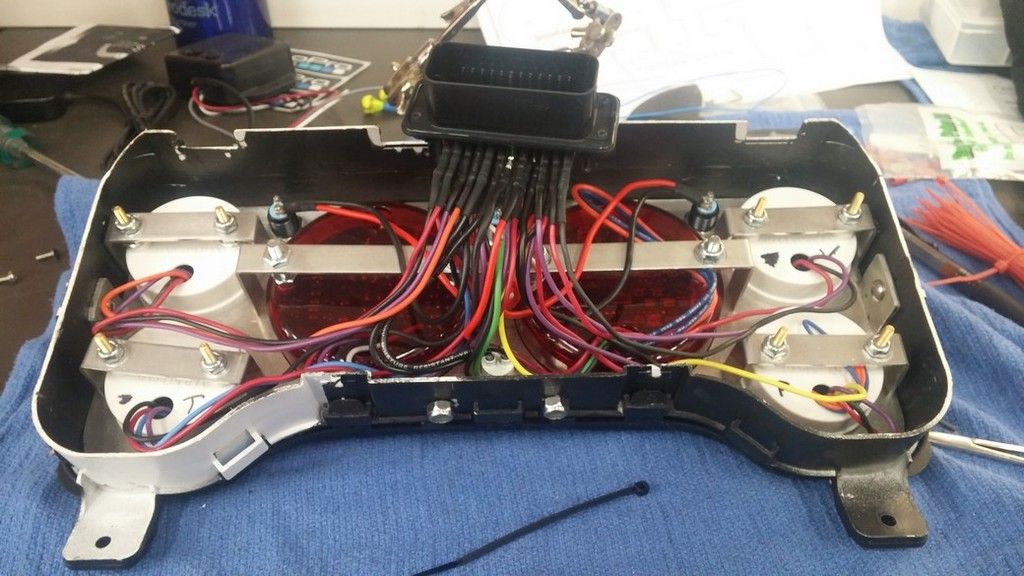

Below is a comparison pic of the 3 different input shafts I have come across. Far left is the 27 spline input, wide bearing (BD50-8), 6 pinion planetary out of the S10 case. Middle is the 23 spline input, narrow bearing, 3 pinion planetary out of my original 98 case. Far right is the 23 spline input, wide bearing, 3 pinion planetary out of the 93 case I picked up this past weekend.

These next couple pics are of the difference in gear cut in the planetary pinion gears. you can see the older pre 94 cut has a wider crown on the teeth vs the post 94 narrow crown.

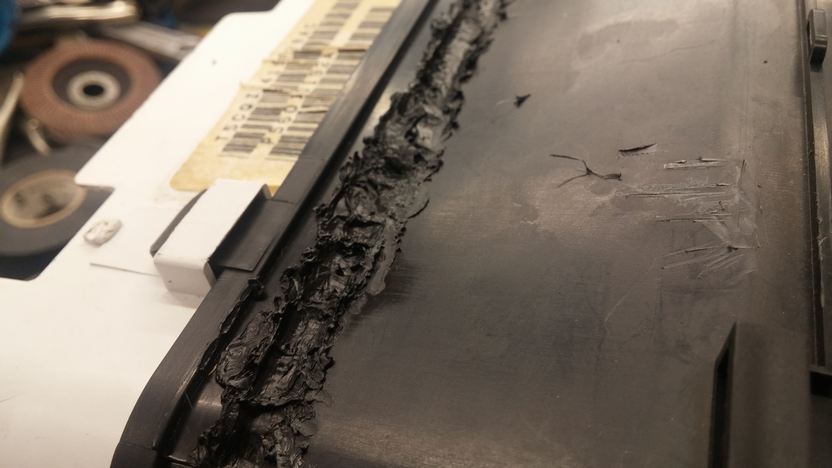

Getting the needle bearings out of the rear of the case is a pain in the ***. I used a Dremel and a few sanding drums to sand down the outer race until it split and I could knock it out with a small slide hammer.

I'm pretty fortunate to have a good friend that rebuilds transmissions at home as a side business so I called him up and took all my parts out to his hot wash tank.

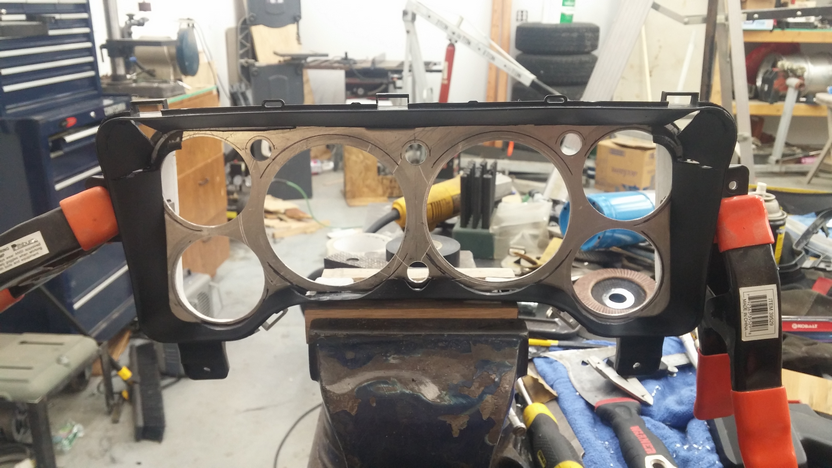

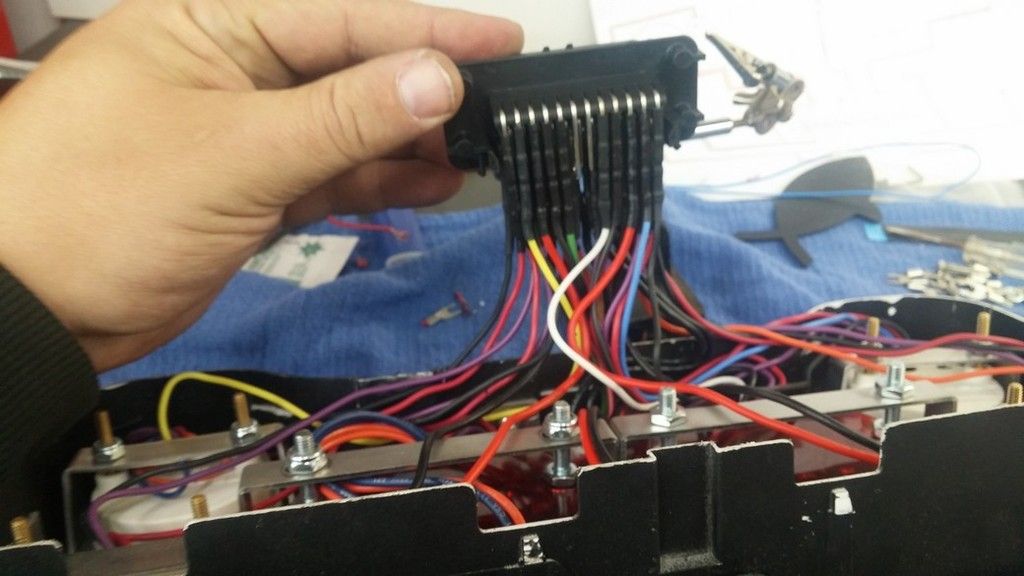

All the clean parts ready to drop in the case. I had to order a couple more bearings and one seal which should be here by the middle of the week and then the case can be final assembled.

This is a pic of the OEM shift comb vs the 2 low comb that came with the kit I bought several years ago from DC4WD.

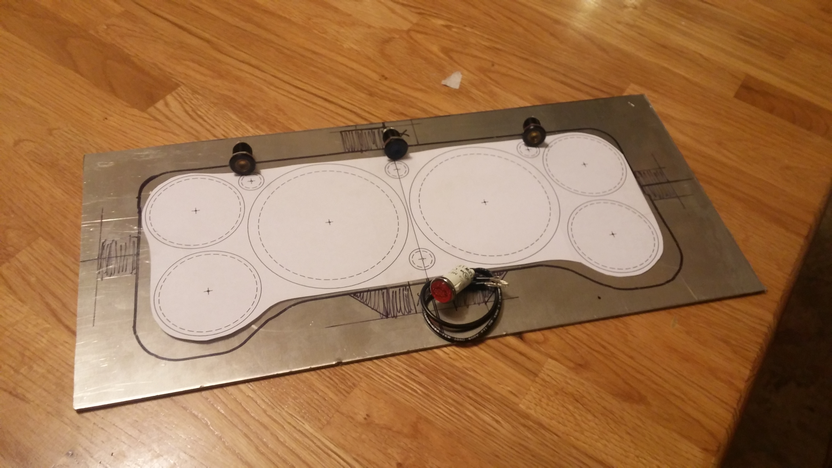

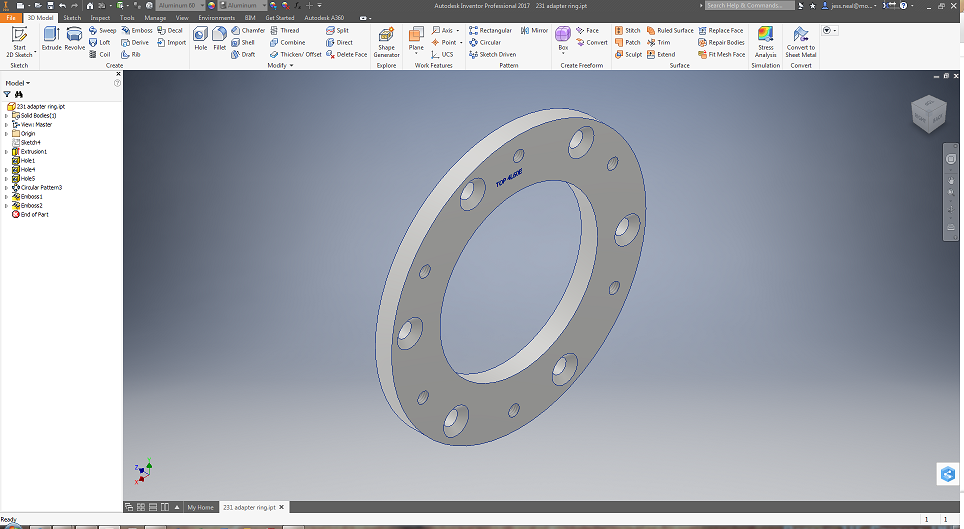

And this is a screen shot of the adapter ring I need to make. It is very similar to FrankZ's adapter plate he made. I haven't decided if I want to make it out of aluminum or steel yet. Any opinions on that?

I uploaded another video to my channel showing the custom tail shaft work including some amateur machining porn

Check it out if you want:

https://www.youtube.com/watch?v=LIXx4JCMO5Q

More later this week.

-Jess