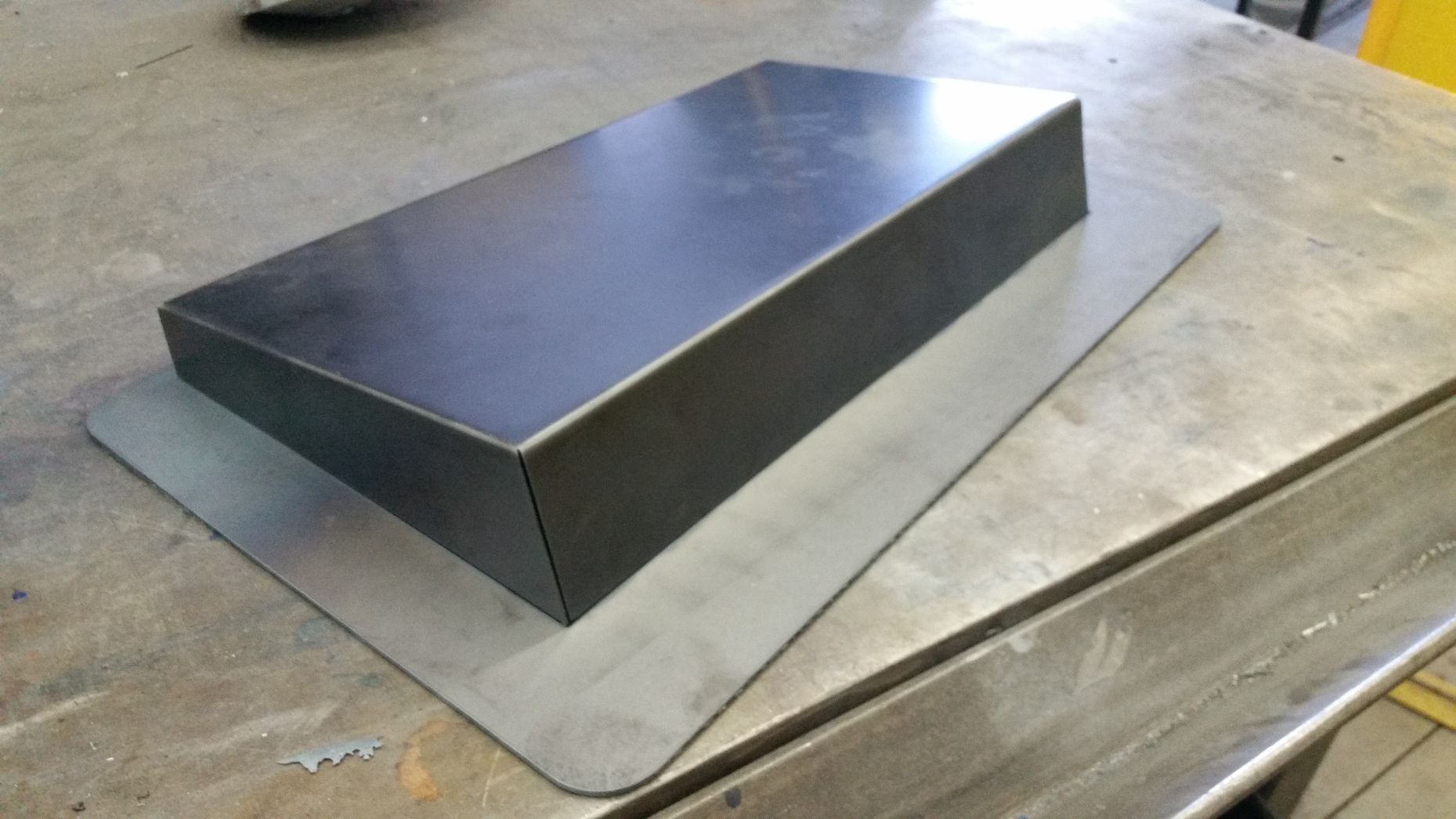

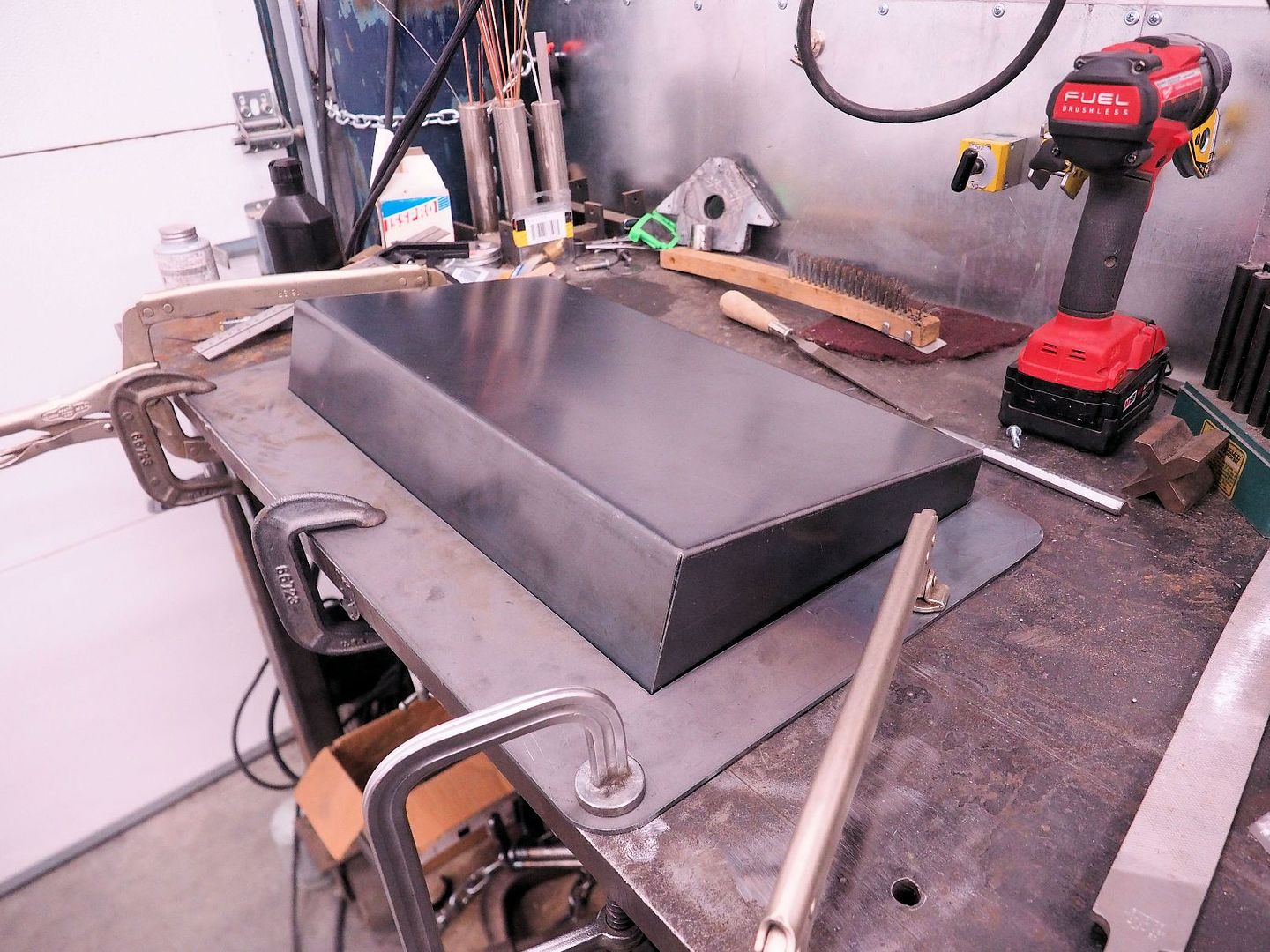

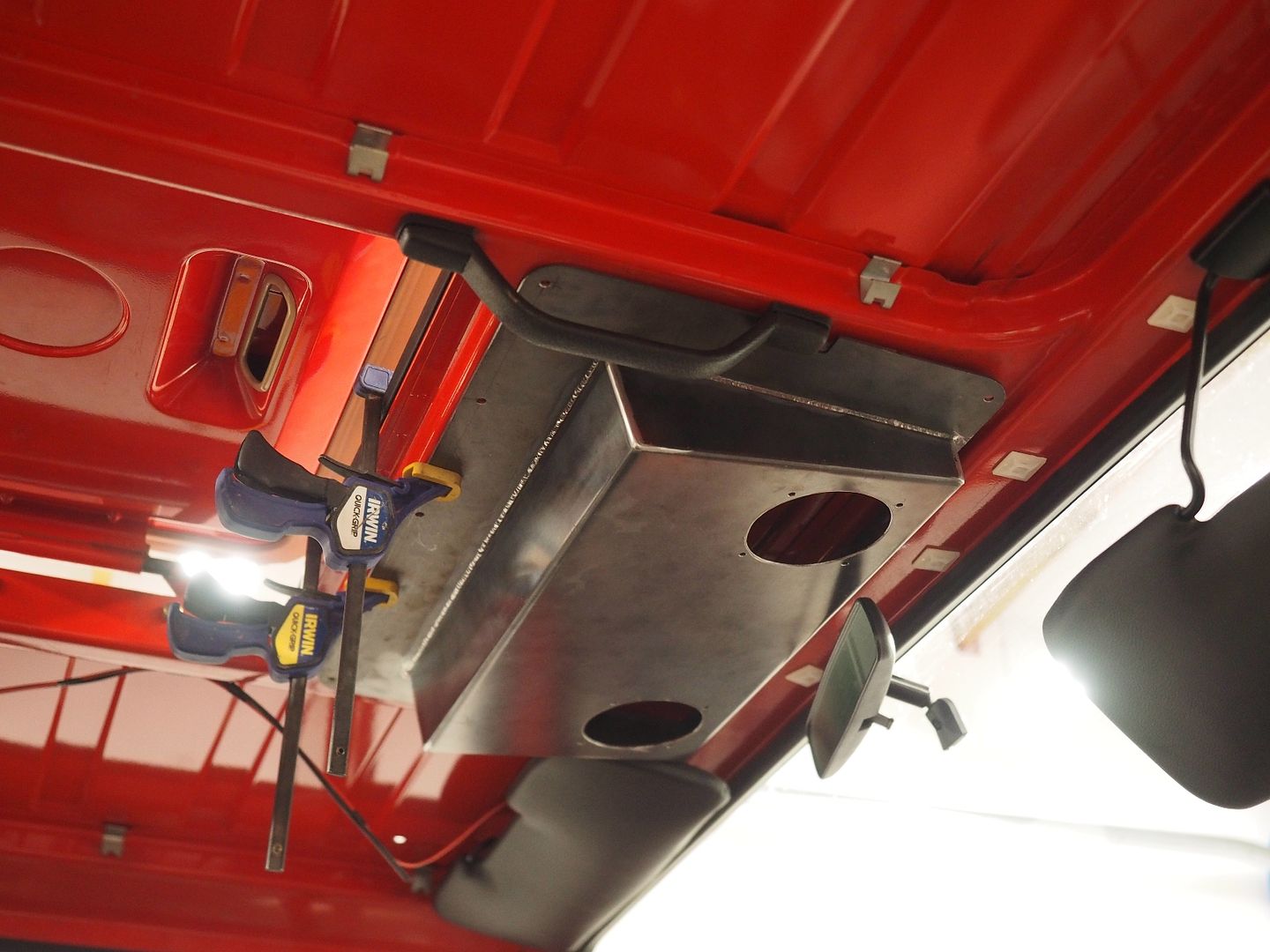

Little more work on the overhead console today. Did some blending on the corners of the box this morning, will touch up the welds before paint as well.

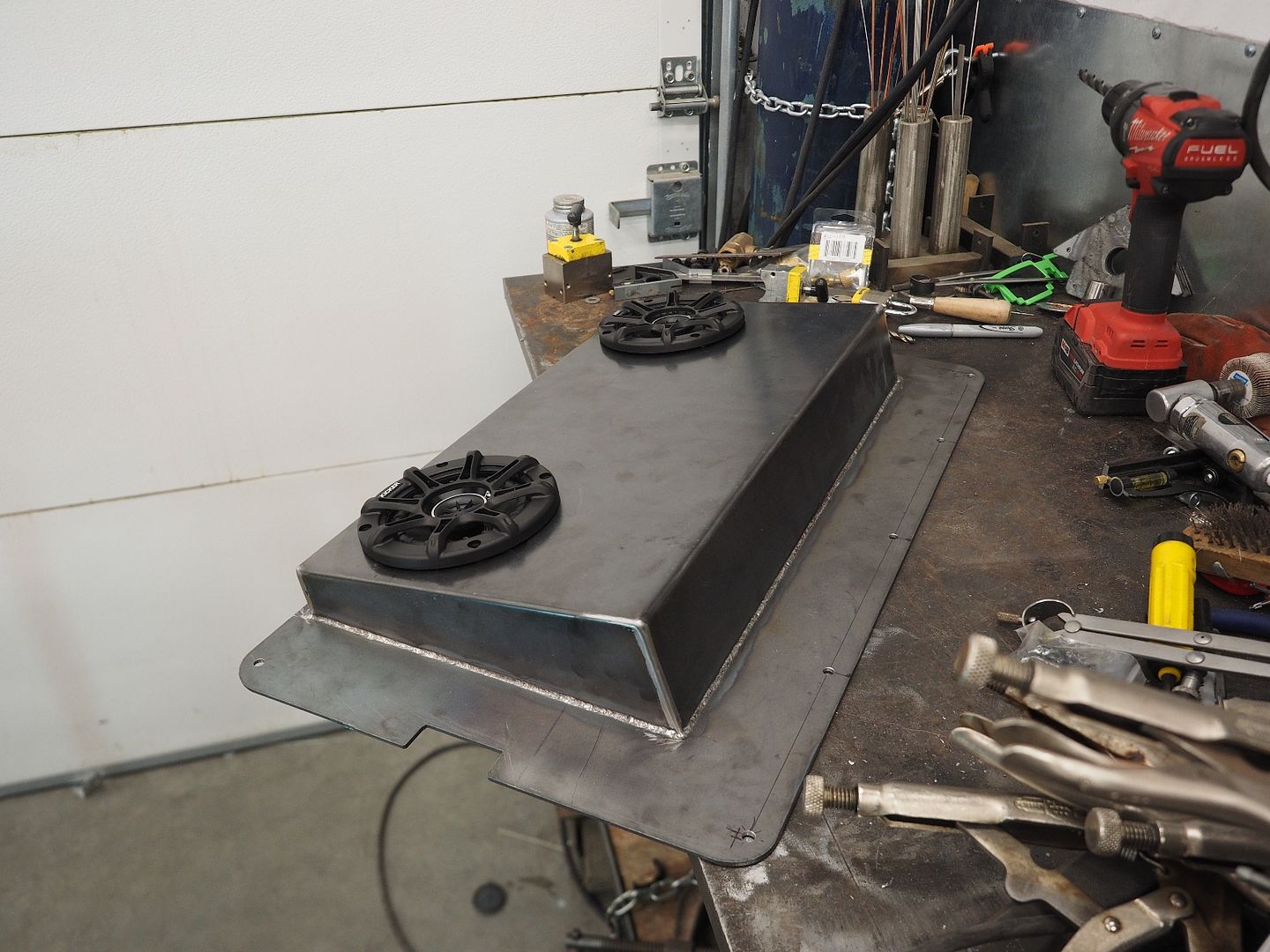

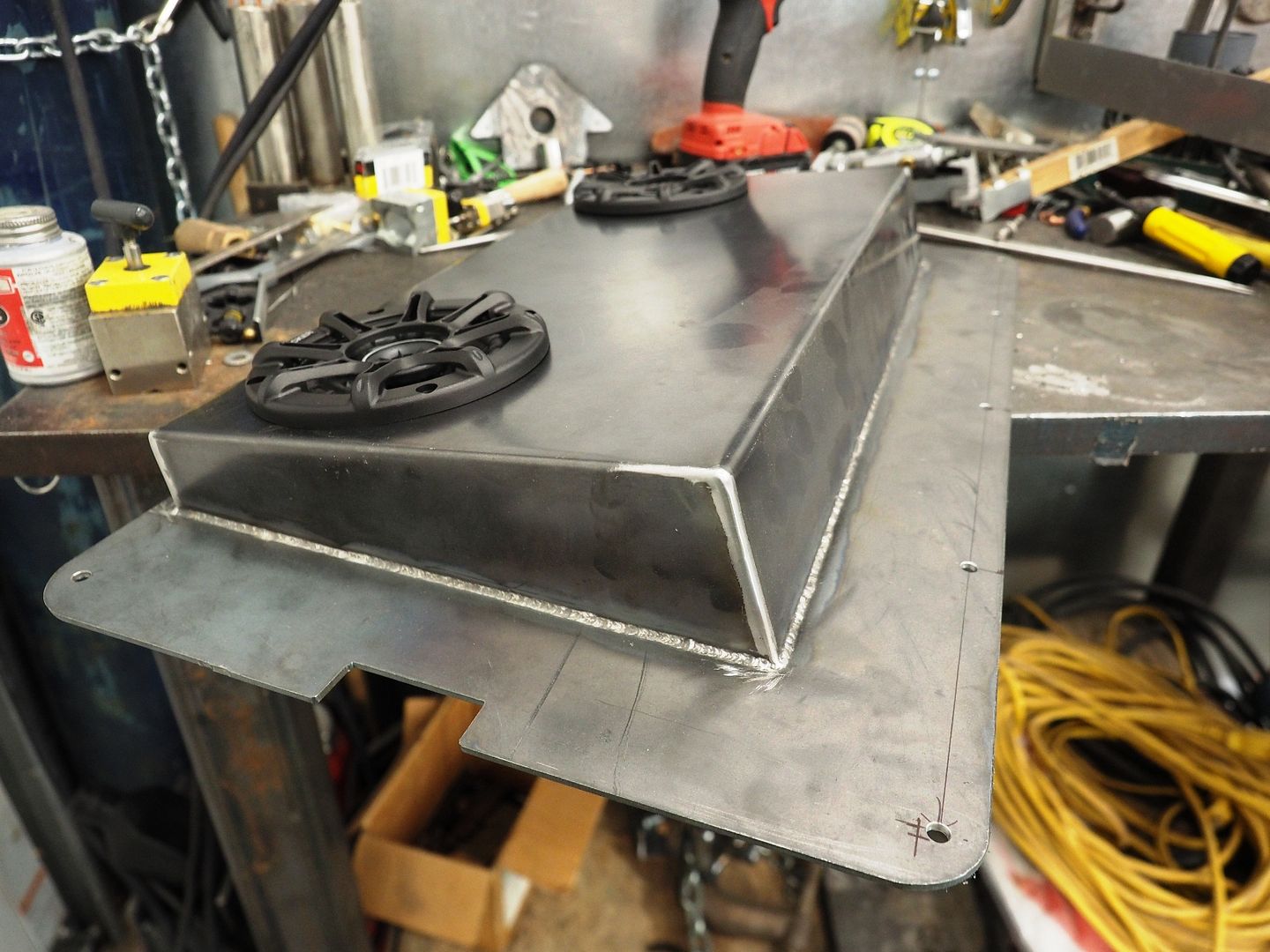

Cut in the speaker holes and drilled the mounting holes in the base.

Not a lot of places to install speakers in the cab so this should work nicely.

Clamping the console in place and using a transfer punch to mark the drill locations.

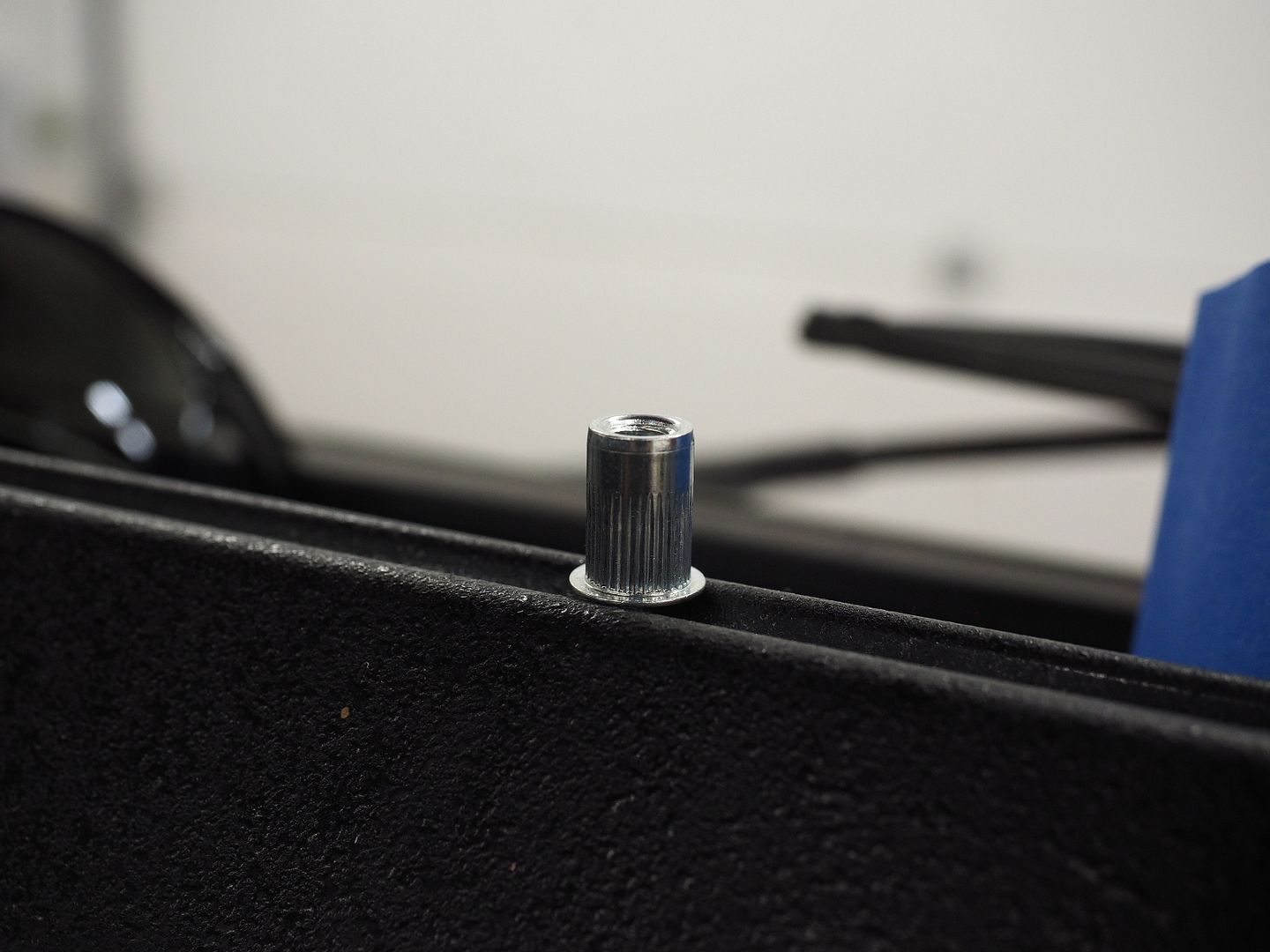

Next we drilled the holes out to the proper size and installed steel rivet nuts in the truck. The rivet nut is installed in the hole and you compress it with a rivet nut tool, it works similar to a pop rivet. The console will now bolt directly to the body and will be very secure.

Rivet nuts set and console in place to see how everything fits. I will use button head hardware during the final install. The factory used rivet nuts for the upper grab handles as well (Gold colored rivet nuts).

More to come.

Hodakaguy